Industrial Oils and Fats and Non-Hazardous Chemicals Flexitank

Scope of Application:

Lubricating oils, lubricant additives, base oils, transformer oils, white oils, tung oil, glycerin, coconut oil, hydraulic oils, industrial gear oils, castor oil, tall oil fatty acids, oleic acid, plasticizers, water reducers, synthetic resins, detergents, disinfectants, surfactants, polyols, feed additives, silicates, brine solutions, propylene glycol, ethylene glycol, polyethers, alkylating agents, herbicides, fertilizers, natural rubber, synthetic latex, etc.

Product Features

Lubricating oils, lubricant additives, base oils, transformer oils, white oils, tung oil, glycerin, coconut oil, hydraulic oils, industrial gear oils, castor oil, tall oil fatty acids, oleic acid, plasticizers, water reducers, synthetic resins, detergents, disinfectants, surfactants, polyols, feed additives, silicates, brine solutions, propylene glycol, ethylene glycol, polyethers, alkylating agents, herbicides, fertilizers, natural rubber, synthetic latex, etc.

Lubricating oils, lubricant additives, base oils, transformer oils, white oils, tung oil, glycerin, coconut oil, hydraulic oils, industrial gear oils, castor oil, tall oil fatty acids, oleic acid, plasticizers, water reducers, synthetic resins, detergents, disinfectants, surfactants, polyols, feed additives, silicates, brine solutions, propylene glycol, ethylene glycol, polyethers, alkylating agents, herbicides, fertilizers, natural rubber, synthetic latex, etc.Chemical Industry

Transportation of Basic Organic Chemicals

Basic organic chemicals like methanol and ethanol are essential raw materials in the chemical industry. These chemicals possess a certain level of hazard and require safe transportation methods. The multilayer composite materials in flexitanks offer excellent chemical resistance and leak prevention. For example, during methanol transport, the inner layer resists methanol’s corrosive properties, while the middle and outer layers prevent leakage and external physical damage, ensuring safety throughout the process.

For chemicals like ethylene glycol, used in producing polyester fibers and antifreeze, flexitanks provide a stable storage environment. Transporting ethylene glycol in flexitanks ensures consistent quality, offering reliable raw material supply for downstream production.

Transportation of Chemical Intermediates

Chemical intermediates, produced during chemical synthesis, have complex and varied properties. Flexitanks can be customized based on the intermediates’ chemical characteristics. For water-sensitive intermediates, waterproof flexitanks can be used; for intermediates with strong odors, the superior sealing prevents odor leakage. This ensures safe and efficient transport within the chemical supply chain.

Pharmaceutical Industry

Transportation of Pharmaceutical Raw Materials

Many pharmaceutical raw materials, such as antibiotic intermediates and excipient precursors, are liquids with strict purity and hygiene requirements. Flexitanks provide a transportation environment compliant with Good Manufacturing Practices (GMP). For instance, the inner layer can be made of pharmaceutical-grade materials to prevent contamination, ensuring the quality and safety of pharmaceutical raw materials.

For highly active raw materials, the flexitank’s sealing and oxygen barrier properties prevent deactivation. Maintaining the activity of these materials during transport is critical to avoid compromising subsequent drug production quality.

Transportation of Pharmaceutical Water

Pharmaceutical water, including purified water and water for injection, is used in drug formulation and cleaning processes. Flexitanks ensure water quality remains uncontaminated during transport. The non-toxic, sterile properties of the inner layer meet the stringent requirements for pharmaceutical water, ensuring high-quality water for drug manufacturing.

Agricultural Industry

Transportation of Liquid Pesticides and Fertilizers

Some pesticides and fertilizers, such as liquid nitrogen fertilizers and plant growth regulators, are in liquid form. Flexitanks facilitate their transport, with materials selected based on the chemical properties of the cargo. For corrosive pesticides, corrosion-resistant materials are used; for volatile fertilizers, strong sealing minimizes evaporation losses, enhancing product efficiency.

Transportation of Plant Extracts

Natural plant extracts like essential oils and pigments are used in agriculture, food, and cosmetics. Flexitanks preserve the active components of these extracts. For example, when transporting plant essential oils, the oxygen barrier and light-blocking properties prevent oxidation and photodegradation, ensuring quality meets usage standards.

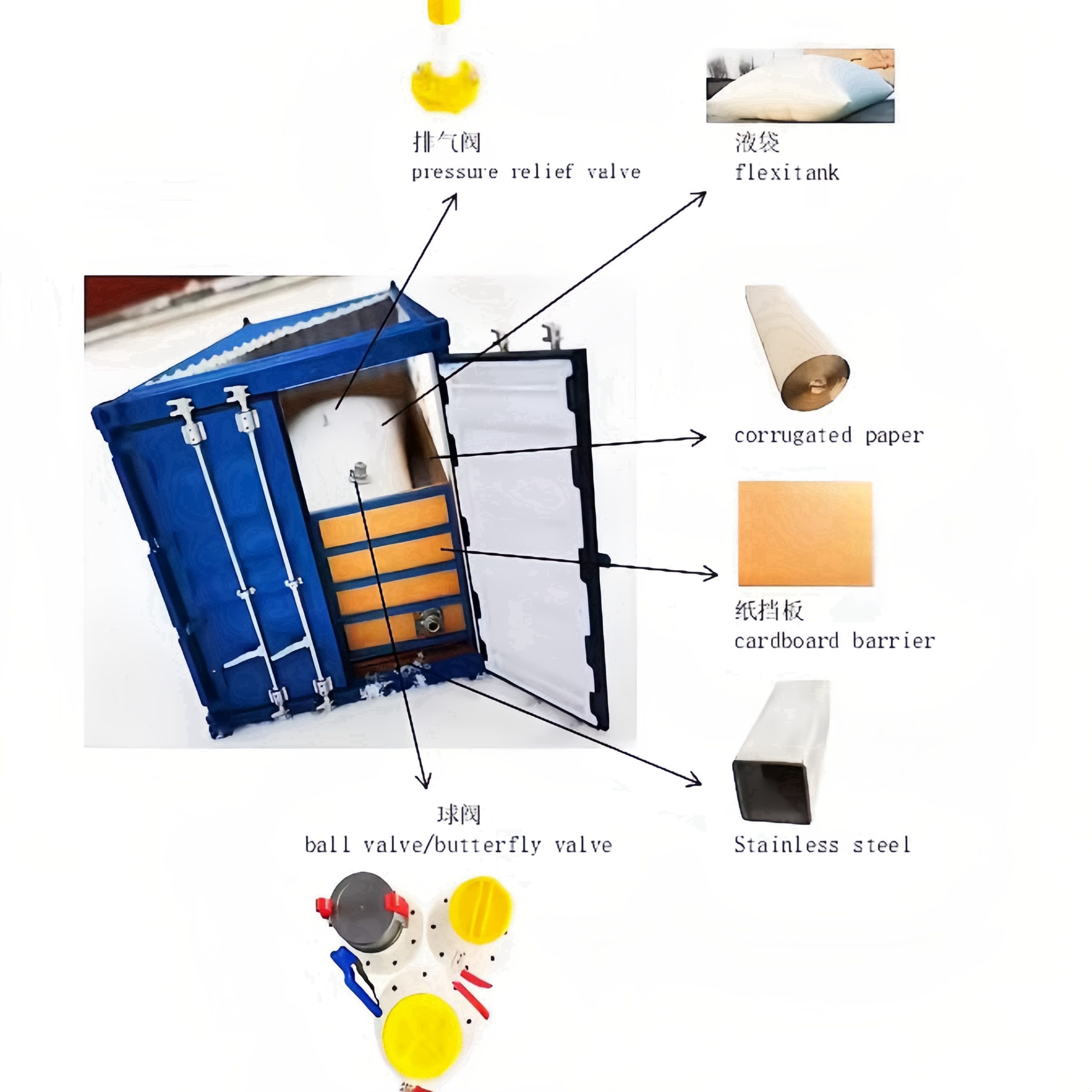

Flexitank Specifications

- Capacity: 16,000–26,000 liters

- Configuration (Customizable based on cargo density):

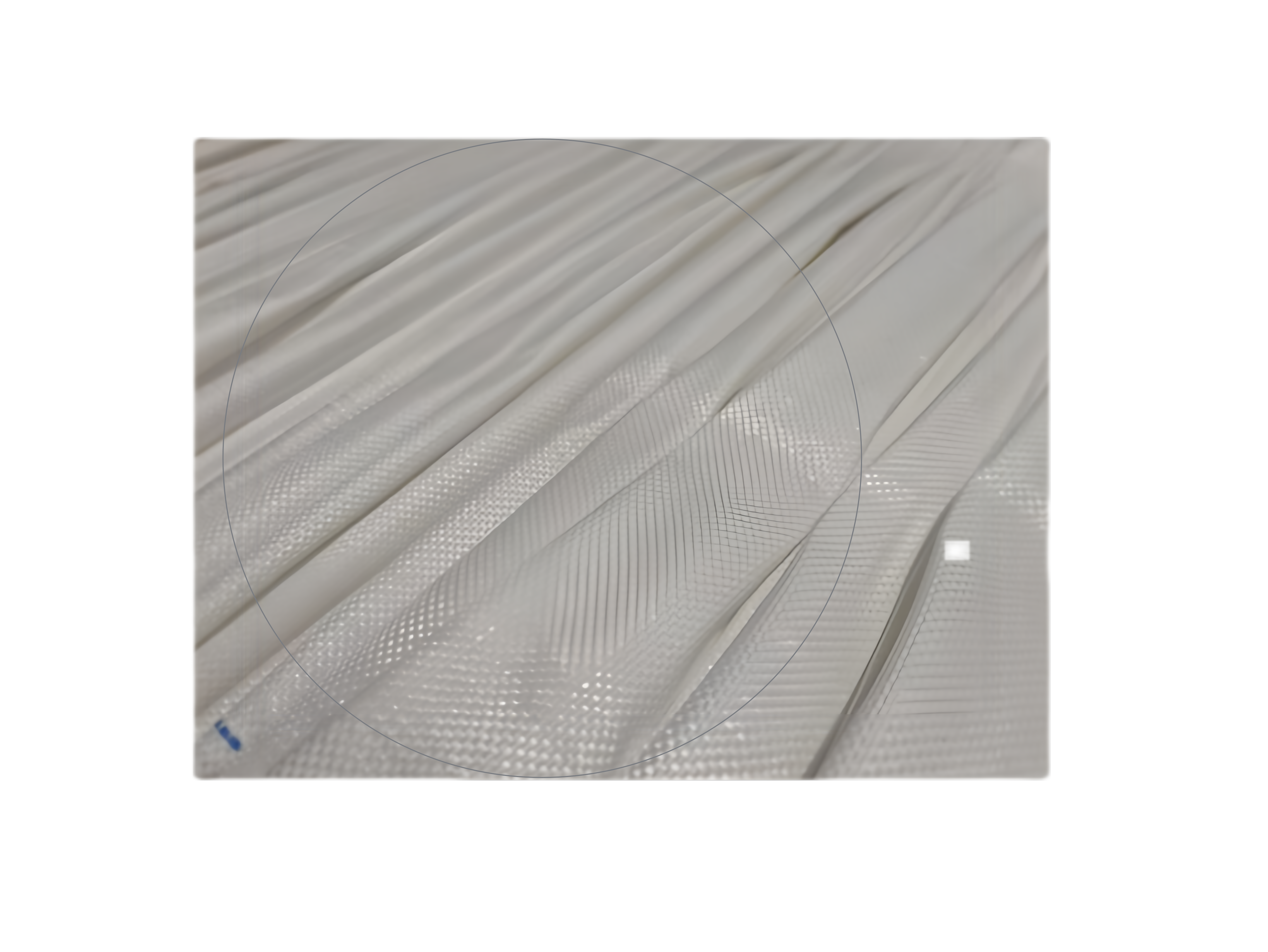

- 2 layers of PE inner film + 1 layer of PP outer film

- 3 layers of PE inner film + 1 layer of PP outer film

- 4 layers of PE inner film + 1 layer of PP outer film

- Temperature Tolerance: -5°C to +80°C

- Carrier: Standard 20-foot container

- Transportation Modes: Inland, maritime, railway, and multimodal freight transport

- Auxiliary Accessories: Food-grade valves, valve shut-off plates, double-layer corrugated paper, partitions, square steel bars, steel frame (optional)

Product Parameters

- Inner PE Layer: Customizable layer count and thickness per client and product needs

- PE Thickness per Layer: 0.13 mm

- Total Weight: Approximately 50 kg

- Tensile Strength:

- Longitudinal: ≥30 MPa

- Transverse: ≥32 MPa

- Tear Strength:

- Longitudinal: ≥120 N/mm

- Transverse: ≥115 N/mm

- Puncture Resistance: ≥1400 g

- Elongation:

- Longitudinal: ≥740%

- Transverse: ≥750%

- Oxygen Permeability: <1 cc/100 m²/24 hours

- Moisture Permeability: 0.3 g/m²/24 hours

- High-Temperature Resistance: 10°C to 80°C

Comparison with Similar Products

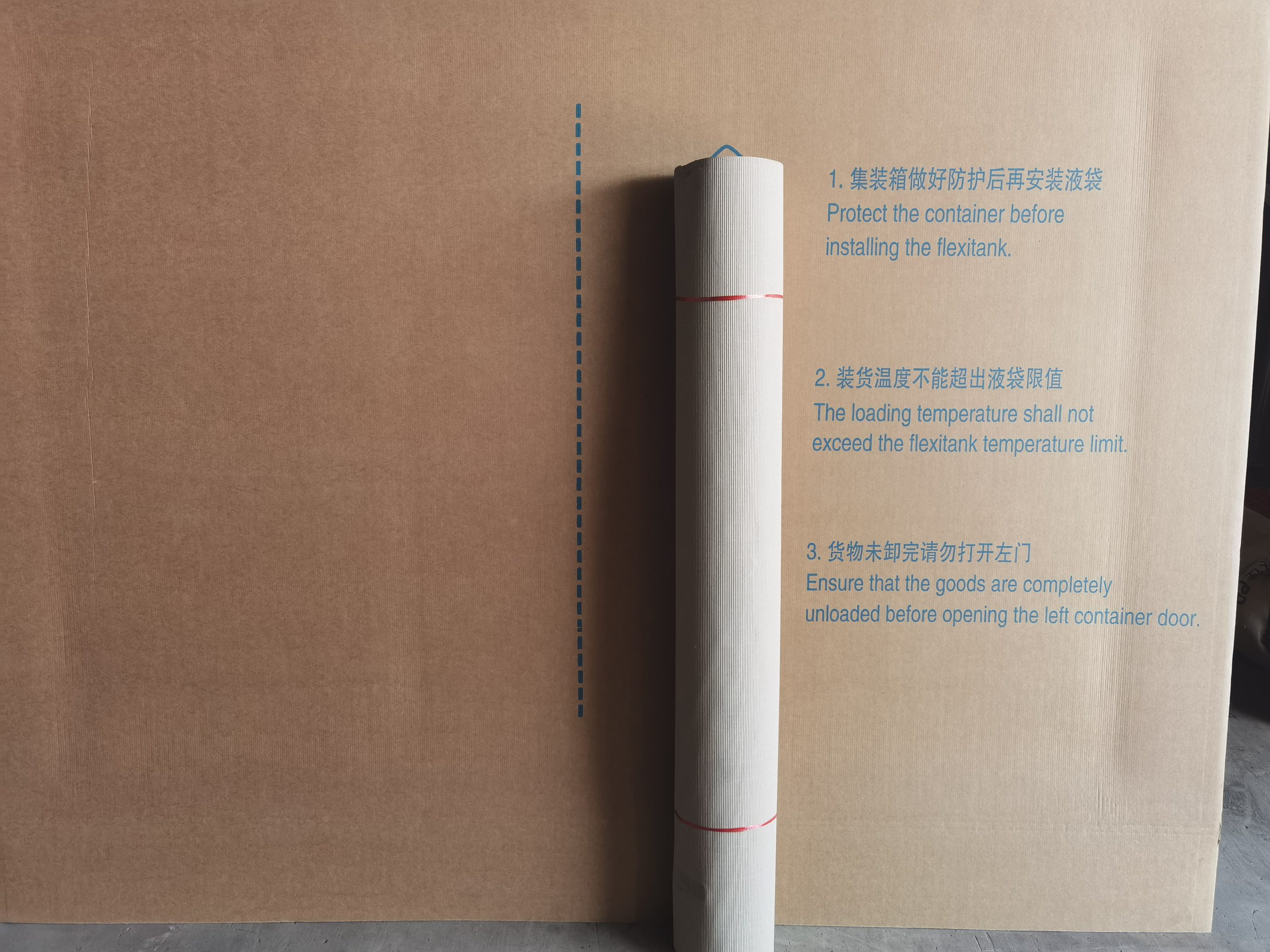

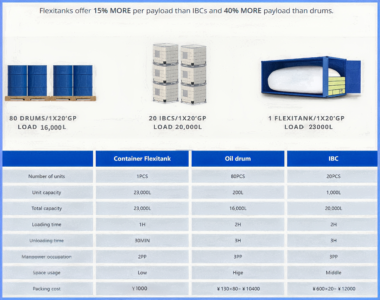

The Optimal Solution for Bulk Liquid Logistics – Flexitank

Flexitanks are the most suitable packaging method for containerized transport of bulk liquids, especially for multimodal transport. Liquids can be pumped directly from storage tanks into flexitanks, eliminating manual palletizing and container stuffing at the origin. Upon arrival, liquids can be unloaded into storage tanks via pumps and pipelines, avoiding manual unloading and warehouse management. Flexitanks streamline the bulk liquid supply chain, improving efficiency and reducing costs.

Flexitank Structural Features

- Multilayer Design:

- Inner Layer: Food-grade polyethylene, in direct contact with cargo, offers chemical stability to prevent reactions, ensuring quality. For instance, it resists corrosion from acidic wine components.

- Outer Layer: High-strength materials like nylon reinforce durability, supporting liquid weight and withstanding transport pressures. The middle layer prevents rupture under heavy loads.

- Wear- and UV-Resistant Materials: Protect against damage during loading, unloading, and transport, resisting UV degradation in sunlight.

Advantages

Cost-Effectiveness

Compared to traditional containers like steel or plastic barrels, flexitanks are more affordable due to lower material costs and efficient space use. For example, transporting edible oil in barrels is costly and space-intensive, while flexitanks maximize container capacity, reducing per-unit costs.

High Flexibility

Flexitanks can be tailored to cargo properties and transport needs, with insulation for temperature-sensitive liquids or oxygen barriers for oxidation-prone ones. Sizes adjust to 20- or 40-foot containers.

Raw Material Analysis

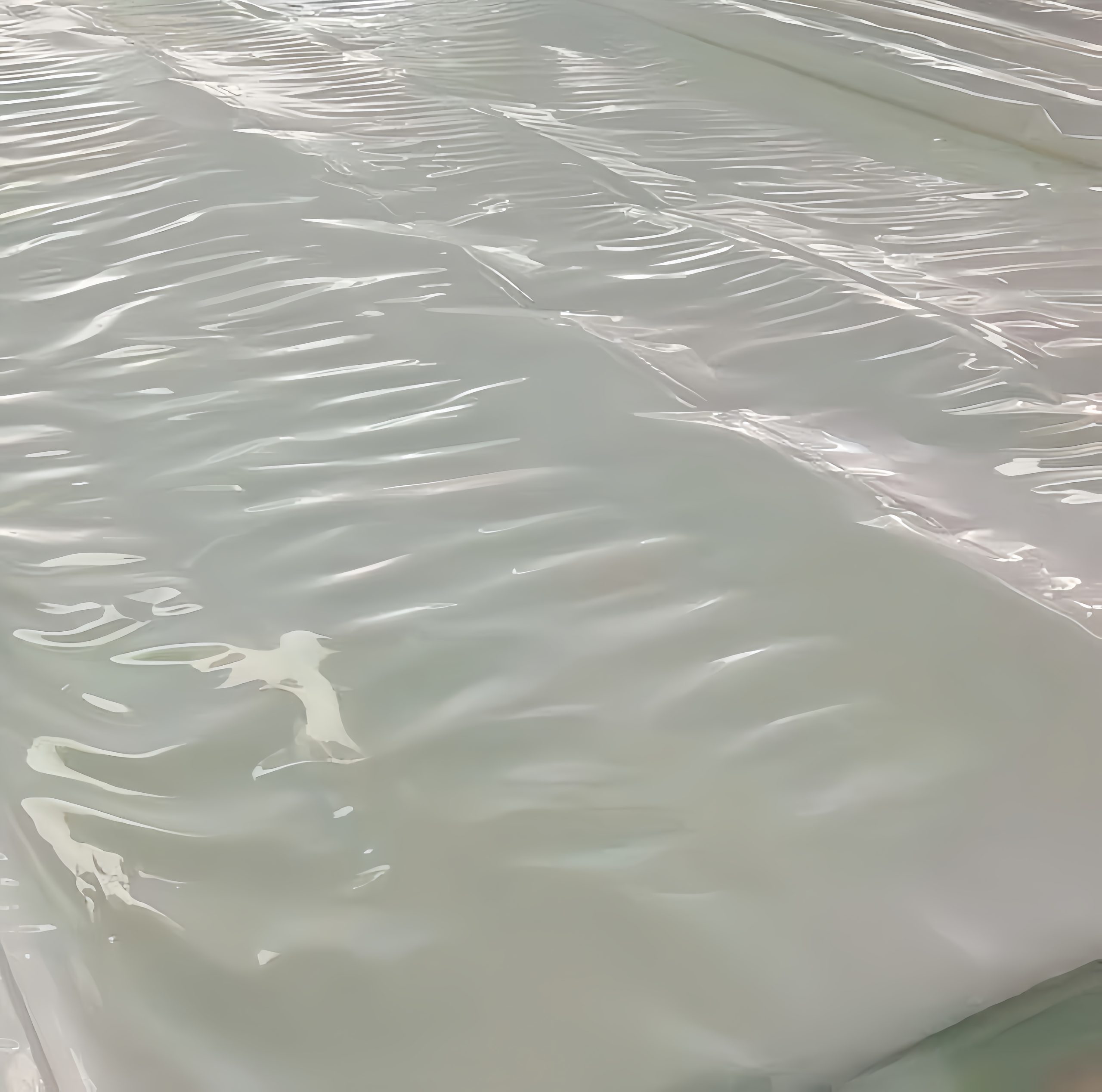

- Inner Film: High-density, high-performance PE film with a unique formula ensuring excellent mechanical properties, flexibility, and heat-seal strength. Advanced production equipment enables automated, continuous manufacturing, exceeding industry standards in tensile strength, elongation, and impact resistance.

- PP Outer Layer: Polypropylene outer bag with tensile strength 15.2% above international standards.

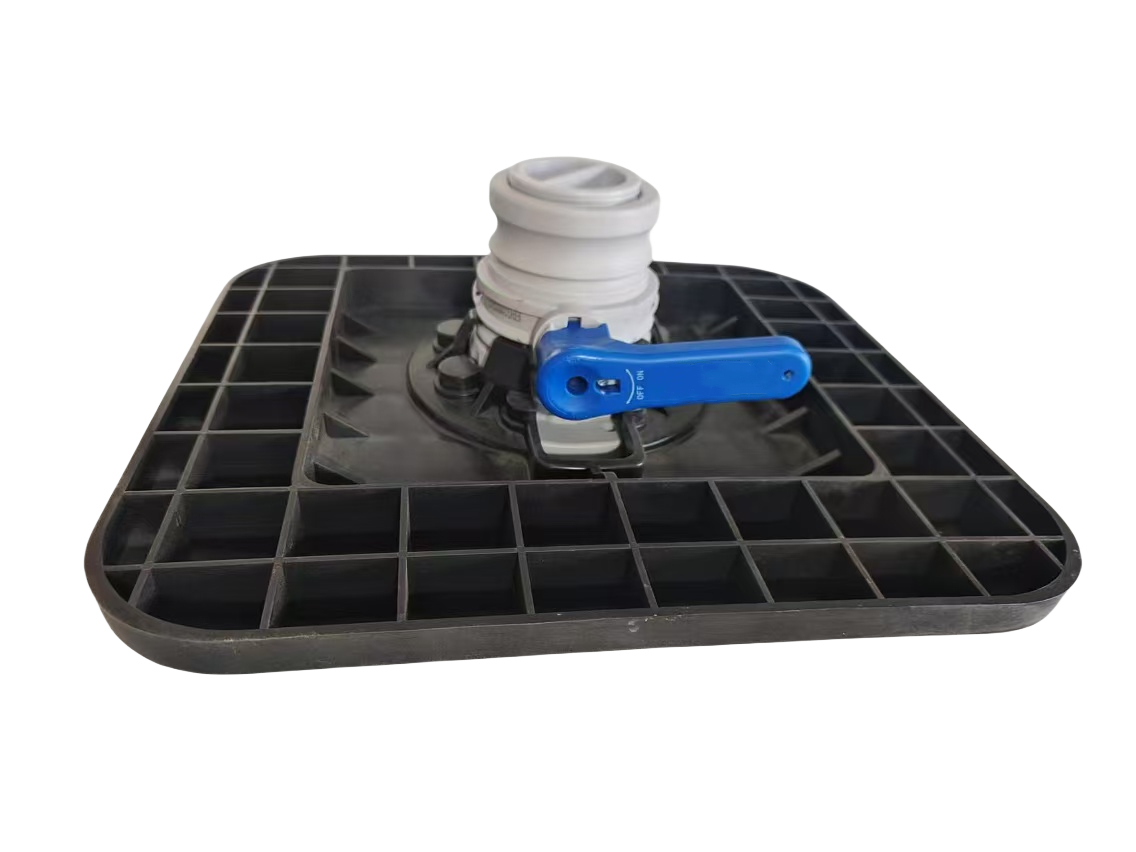

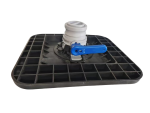

Ball & Butterfly Valves

Overview

CSS flexitank ball valves, designed for flexitanks, feature flange screw connections for easy installation. The valve body is non-toxic and corrosion-resistant.

Features

- Triple sealing (valve plate, threaded cap, dust cover) prevents leaks comprehensively.

- Non-toxic, corrosion-resistant, high-temperature-resistant sealing ring.

- Self-locking handle ensures safe, reliable operation.