Food grade flexitank

Scope of Application: Edible oils, palm oil, wine, various concentrated fruit juices, food additives, various syrups, sorbitol, soy sauce, yellow wine, mineral water, malt extract, etc.

Scope of Application

Edible oils, palm oil, wine, various concentrated fruit juices, food additives, various syrups, sorbitol, soy sauce, yellow wine, mineral water, malt extract, etc.

Edible oils, palm oil, wine, various concentrated fruit juices, food additives, various syrups, sorbitol, soy sauce, yellow wine, mineral water, malt extract, etc.Transportation of Edible Oils

Whether it’s vegetable oils (e.g., soybean oil, corn oil, palm oil) or animal oils (e.g., fish oil), contamination and deterioration must be avoided during transportation. The multilayer structure of a flexitank prevents external impurities from entering, and its materials meet food hygiene standards, ensuring the quality and safety of edible oils. In large-scale edible oil trade, flexitanks maximize the use of container space, improving transportation efficiency.

Wine Transportation

Wine transportation is a key application for flexitanks. Wine has strict environmental requirements during transport, needing protection from excessive oxidation and temperature fluctuations. The oxygen barrier layer inside a flexitank effectively reduces contact between wine and oxygen, slowing down oxidation. Additionally, the chemical stability of flexitank materials prevents any impact on the wine’s flavor and quality. For example, transporting wine from French wine regions to global markets using flexitanks ensures quality while enabling large-scale, efficient delivery.

Beer Transportation

Flexitanks provide an excellent sealed environment, preventing carbon dioxide leakage. If CO2 escapes during beer transportation, it affects taste and foam quality. Flexitanks help maintain the carbonation level of beer, ensuring consumers enjoy a fresh taste upon delivery.

Fruit Juice Transportation

Fresh fruit juices are rich in nutrients like vitamin C, which can degrade due to oxidation or microbial contamination during transport. Flexitanks, with their superior sealing and hygienic design, effectively prevent oxidation and microbial intrusion. For instance, transporting freshly squeezed juice from tropical fruit regions to consumer markets using flexitanks preserves freshness and nutritional value.

Product Features

Made from imported food-grade raw materials and produced in a food-grade standard workshop, ensuring no secondary contamination of the loaded liquids. This maintains product quality, keeping goods pure and safe upon arrival at their destination.

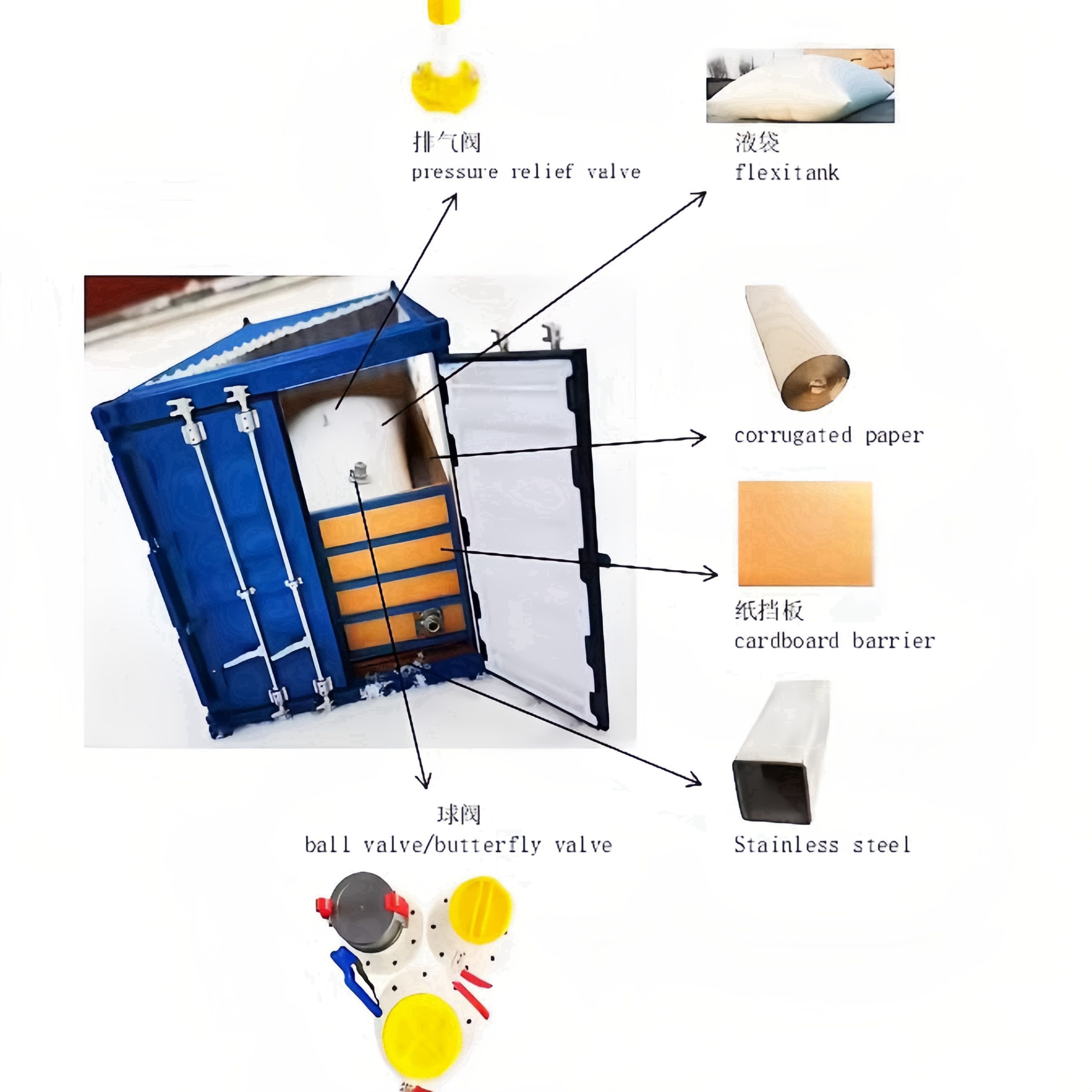

Flexitank Specifications

(Customizable based on the density of the cargo)

- Capacity: 16,000–26,000 liters

- Configuration:

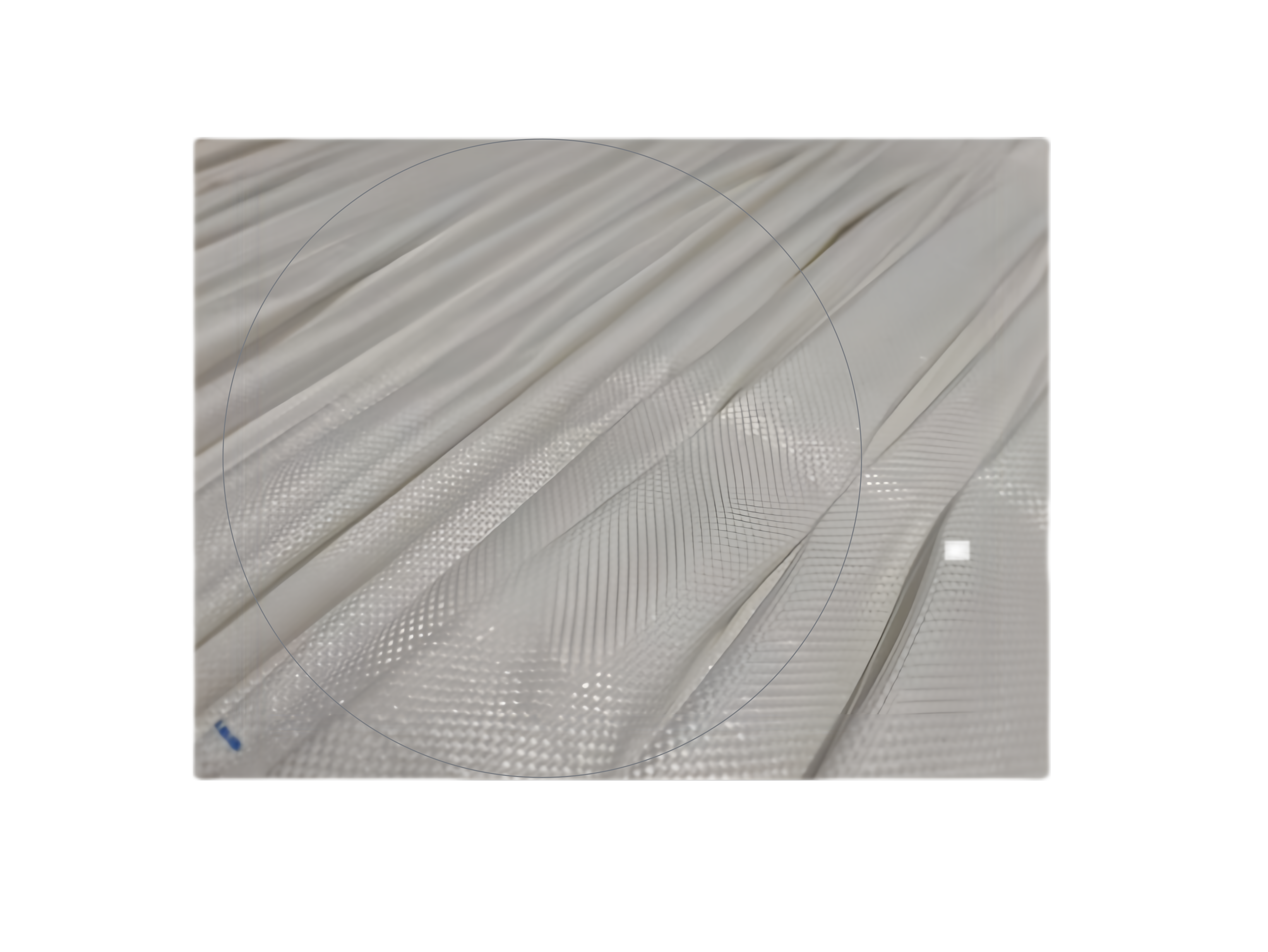

- 2 layers of PE inner film + 1 layer of PP outer film

- 3 layers of PE inner film + 1 layer of PP outer film

- 4 layers of PE inner film + 1 layer of PP outer film

- Operating Temperature Range: -20°C to +80°C

- Carrier: Standard 20-foot container

- Transportation Modes: Inland, maritime, railway, and multimodal freight transport

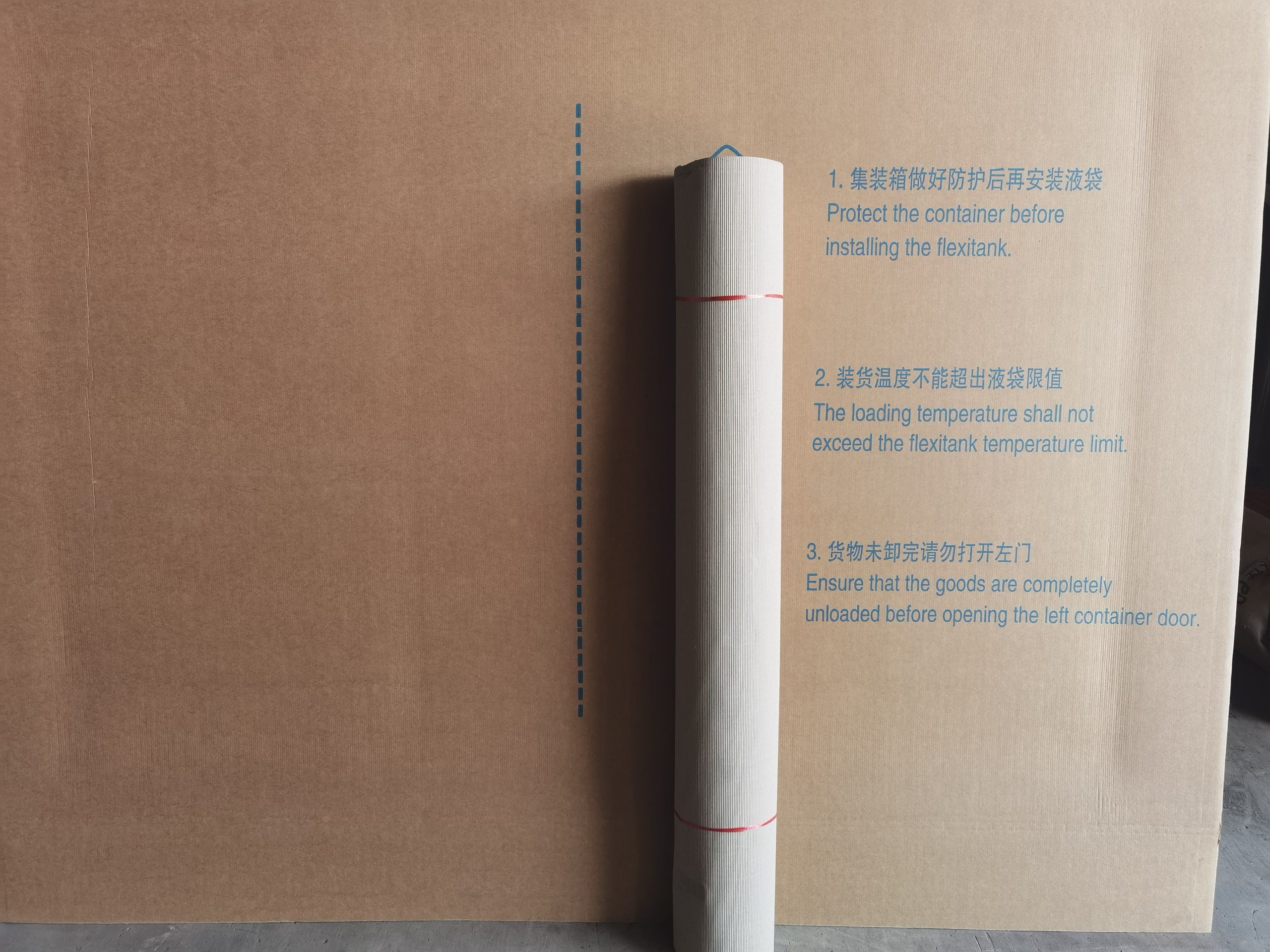

- Auxiliary Accessories: Food-grade valves, valve shut-off plates, double-layer corrugated paper, partitions, square steel bars, steel frame (optional)

Product Parameters

- Inner PE Layer: Number and thickness of PE layers customizable per client and product requirements

- PE Thickness per Layer: 0.13 mm

- Total Weight: Approximately 50 kg

- Tensile Strength:

- Longitudinal: ≥30 MPa

- Transverse: ≥32 MPa

- Tear Strength:

- Longitudinal: ≥120 N/mm

- Transverse: ≥115 N/mm

- Puncture Resistance: ≥1400 g

- Elongation:

- Longitudinal: ≥740%

- Transverse: ≥750%

- Oxygen Permeability: <1 cc/100 m²/24 hours

- Moisture Permeability: 0.3 g/m²/24 hours

- High-Temperature Resistance: 10°C to 80°C

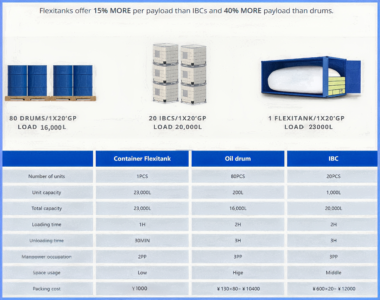

Comparison with Similar Products

The Optimal Solution for Bulk Liquid Logistics – Flexitank

Flexitanks are the most suitable packaging method for containerized transport of bulk liquid food products, especially for multimodal transport. Liquids can be pumped directly from storage tanks into flexitanks, eliminating manual palletizing and container stuffing at the origin. Upon reaching the destination, liquids can be unloaded into storage tanks via pumps and pipelines, removing the need for manual unloading and warehouse management. Using flexitanks simplifies the bulk liquid logistics supply chain, enhances overall operational efficiency, and reduces logistics costs.

Flexitank Structural Features

- Multilayer Design:

- Inner Layer: Food-grade polyethylene, in direct contact with the liquid cargo, offers excellent chemical stability to prevent reactions with other materials, ensuring cargo quality. For example, when transporting wine, this layer prevents the wine’s acidic components from corroding other parts of the flexitank.

- Outer Layer: High-strength materials like nylon reinforce the flexitank’s overall durability, enabling it to withstand the weight of the liquid and pressures or impacts during transport. For instance, when filled with tons of liquid, the middle layers prevent rupture.

- Wear- and UV-Resistant Materials: Protect the flexitank from external damage during loading, unloading, and transport. Especially during open storage or sea transport, the outer layer resists UV degradation from sunlight.

Flexitank Advantages

Cost-Effectiveness

Compared to traditional liquid transport containers like steel or plastic barrels, flexitanks have lower costs due to affordable materials and efficient use of container space, reducing the number of packaging units needed. For example, transporting large volumes of edible oil in barrels is costly and space-intensive, while a flexitank can carry more oil in a single container, lowering per-unit transport costs.

High Flexibility

Flexitanks can be customized based on the properties of the liquid cargo and transport requirements. For liquids with specific temperature needs, insulation can be added to the outer layer; for oxidation-sensitive liquids, an oxygen barrier can be included. Flexitank sizes can also be adjusted for 20- or 40-foot containers.

Raw Material Analysis

- Inner Film: High-density, high-performance PE film with a unique formula ensuring excellent mechanical properties, flexibility, and heat-seal strength. Advanced domestic PE film production equipment and feeding systems enable fully automated, uninterrupted, and unmanned continuous production, with physical properties (tensile strength, elongation at break, dart impact strength, thickness uniformity, and flexibility) exceeding industry standards.

- PP Outer Layer: Polypropylene outer bag with tensile strength exceeding international standards by 15.2%.

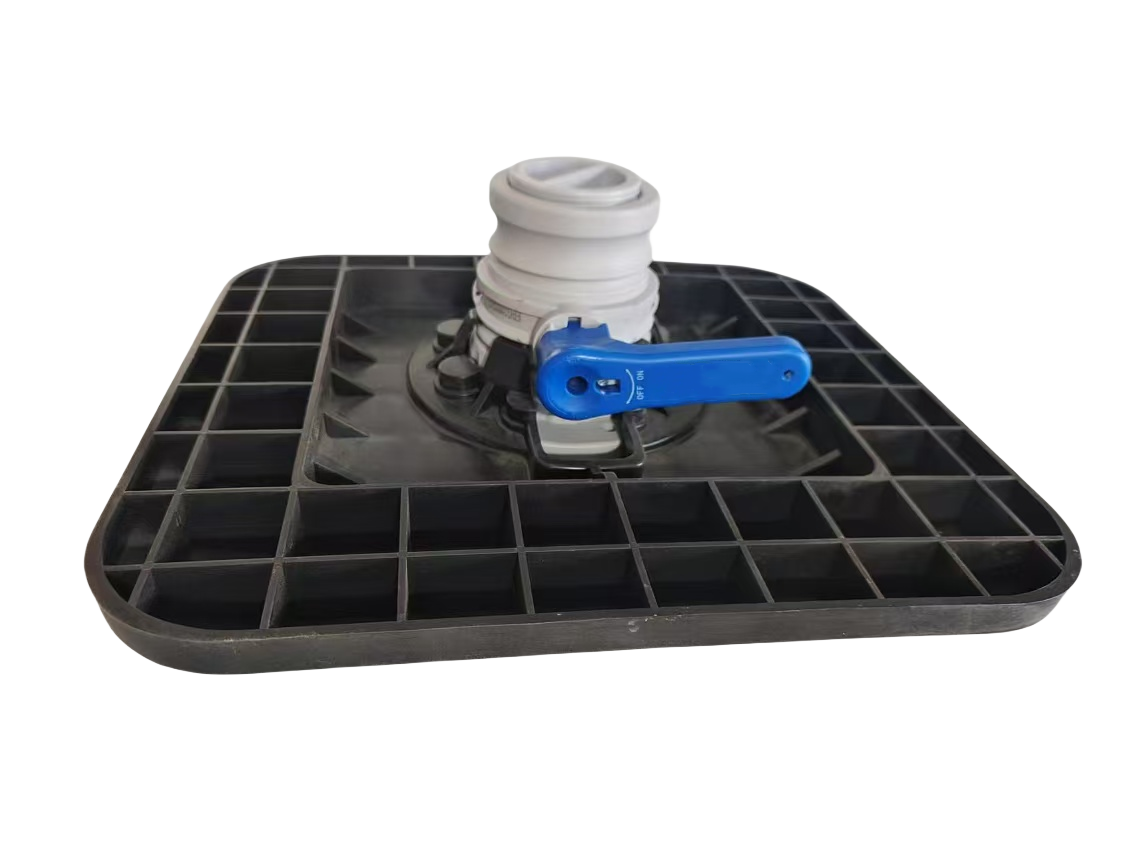

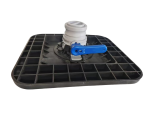

Ball & Butterfly Valves

Product Overview

CSS flexitank ball valves are designed specifically for flexitanks, featuring flange screw connections for easy and simple installation. The valve body is made of non-toxic, corrosion-resistant material.

Valve Features

- Triple sealing structure (valve plate, threaded cap, dust cover) prevents leaks comprehensively.

- Non-toxic, corrosion-resistant, high-temperature-resistant sealing ring.

- Self-locking handle ensures safe, reliable, and convenient operation.